Drug shortages continue to strain pharmacy budgets, impact clinical workflows, and create friction across care delivery. About 92% of pharmacy staff describe shortages as a constant burden, and more than half last over two years. As shortages grow more complex, you need models that forecast operational impact, not only occurrence.

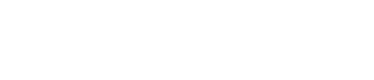

Understanding clinical disruption, labor requirements, and financial exposure helps you reallocate inventory and coordinate substitutions before a shortage escalates. The most effective approaches combine utilization history, supplier reliability trends, market-wide activity, and real-time purchasing data from over 3,000 hospitals.

Put a Stronger Predictive Model in Place

Health systems can strengthen drug shortage forecasting by consolidating real-time purchasing data, utilization trends, supplier performance, and market signals within a single predictive framework. Platforms that analyze national purchasing patterns can anticipate shortages up to 90 days in advance. A unified model creates a repeatable workflow for evaluating severity, coordinating substitutions, reallocating stock, and informing senior leadership early.

Identify Which Medications Create the Greatest Operational Exposure

Multi-year utilization trends reveal which medications create the highest operational risk.

- High-acuity drugs with limited or no viable alternatives force rapid clinical adjustments

- Medications with seasonal spikes can strain budgets and staffing patterns when demand rises

- Long-term or chronic shortages create sustained pressure on substitutes, pushing volatility into adjacent drug classes and triggering secondary shortages

Pinpointing these shortages early shows you where disruption is likely to emerge and gives you the lead time to redirect stock, adjust workflows, or prevent escalation.

Track Supplier Reliability to Estimate Risk and Duration

Supplier reliability is one of the strongest indicators of shortage likelihood and duration.

Fulfillment consistency, partial shipments, and recurring delays are tracked in ShortageCheck to help quantify risk over time. Manufacturer factors, including production slowdowns, recalls, or capacity constraints, refine the picture even further. Reliability scoring consolidates these inputs so you can determine which medications will likely require contingency planning across the system.

Use System-Wide Operational Signals to Model Real-World Impact

A system’s operational footprint reveals how quickly a shortage can disrupt care. Comparing inventory across hospitals highlights which sites are immediately vulnerable and which have supply that can be redistributed. Estimating workflow burden clarifies the lift required for safe alternatives, including:

- EHR updates

- Automation changes

- Medication policy adjustments

Downstream effects often extend beyond pharmacy, influencing compounding operations, formulary pathways, and clinical treatment plans. Modeling these impacts early helps you prioritize mitigation steps and deploy resources before frontline operations feel pressure.

Incorporate Market-Wide Intelligence to Get Ahead of Formal Announcements

Market-wide intelligence like order cancellations, rapid consumption shifts, and inconsistent fulfillment patterns often signal upstream pressure. Tracking purchasing behavior across peer systems adds another layer of insight, especially when national datasets show swift changes.

Integrating these signals into shortage committee agendas and executive briefings ensures you see risk trajectories while action is still possible and supports tighter coordination across pharmacy, supply chain, operations, and finance.

Build Scenario Models That Quantify Duration, Cost, and Clinical Disruption

Scenario modeling translates signals into planning inputs. Supplier reliability data and market indicators help estimate best-case, moderate, and severe timelines so you understand how long mitigation may be needed. Labor and cost exposure estimates clarify the operational lift associated with substitutions, increased compounding, or transitions to higher-priced alternatives, which can be further supported by CostCheck for pricing data. These models support informed decisions about inventory redistribution, contracting, and resource allocation.

Get Proactive with ShortageCheck

ShortageCheck provides a system-wide view and supports proactive drug shortage management through predictive analytics, operational intelligence, and centralized team communication. Request a demo to see how predictive modeling fits into your shortage strategy.