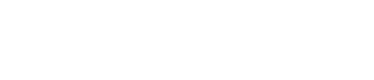

Pharmacy and supply chain teams can only respond to drug shortages at speed when they share the same data, interpret risks the same way, and act through aligned workflows. Recent national figures show how urgent this coordination has become. Published in June 2025, the Vizient “Beyond the Shortage” 2024 report found hospitals spent more than 20 million hours and nearly 900 million dollars on shortage management, which is more than twice the labor burden reported in 2019.

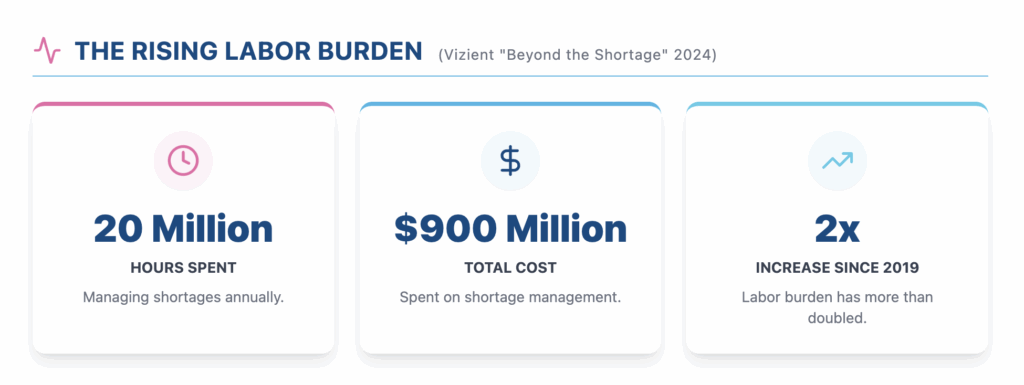

ASHP recorded 323 active shortages in the first quarter of 2024, with 235 still active as of February 2025, and more than 1,400 shortages in the past decade. As these pressures rise, coordinated processes give leaders the ability to anticipate risk earlier, guide frontline adjustments, and maintain stable care delivery across all sites.

Build a Shared Operational Picture With Real-Time, Systemwide Data

Most coordination gaps begin with fragmented visibility. Tools such as ShortageCheck consolidate inventory, utilization, and purchasing information from across 3,000+ hospitals into a unified source of truth, eliminating siloed information.

When data is unified across facilities, leaders can compare on-hand counts, burn rates, substitutes, and expected runout dates without waiting for manual reports. Shared definitions for shortage tiers and prioritization criteria create a consistent foundation for substitution decisions, purchasing actions, and redistribution strategies. Predictive analytics strengthen this picture by modeling where operational risk is likely to rise and how soon. Systemwide thresholds, such as days on hand or criticality scores, ensure teams act at the right moment and for the right reasons.

Use Predictive Forecasting to Move From Reactive to Proactive

With shared data in place, forecasting signals help teams anticipate supply interruptions instead of reacting to them. Predictive analytics can provide up to ninety days of advance notice with an average lead time of 52 days, transforming reactive shortage management into strategic planning.

Prioritizing shortages by clinical impact, burn rate, and procurement risk ensures resources are focused on the most consequential threats. Regular forecast review meetings keep pharmacy and supply chain leaders aligned on shifting conditions, while concise summaries distributed to clinical and operational stakeholders will help reduce unexpected disruptions and strengthen readiness.

Create a Cross-Functional Shortage Response Team

Forecasting only delivers value when organizational structures and unified technology platforms support coordinated action. A cross-functional shortage response team should include members from pharmacy, clinical operations, supply chain, contracting, and finance.

- Clear role definitions for shortage tiering, vendor engagement, and communication prevent decision bottlenecks and reduce delays.

- Shared dashboards give team members a unified operational picture that strengthens coordination between purchasing, clinical decision-makers, and site leadership.

- A systemwide playbook documents redistribution rules, escalation criteria, and response tiers so individual sites are not forced to improvise during high-pressure events.

- Standard communication templates make it easier to provide guidance on substitutions, conservation expectations, and operational updates.

Strengthen Procurement and Pharmacy Alignment to Reduce Cost and Waste

Once team structures are established, tight alignment between procurement and pharmacy ensures sourcing choices support clinical priorities. Tools like CostCheck consolidates pricing data, contracts, invoices, and consumption across the system, giving teams real-time clarity on cost-effective alternatives.

Identifying clinically appropriate substitutes that offer better availability or lower cost reduces pressure on budgets and frontline operations, a task that’s nearly impossible to perform manually given the thousands of NDCs and constantly shifting market conditions. With pharmacy teams already stretched thin, continuous monitoring of price shifts and market volatility protects margins and prevents overcharges during constrained periods. Tracking financial baselines also equips leaders to communicate cost pressures and operational progress to executive stakeholders.

Create Standardized Substitution Pathways That Accelerate Decision-Making

Standardized substitution pathways limit delays when high-risk or frequently constrained medications come under pressure. To make sure those decisions are put into practice quickly, systemwide communication tools distribute real-time updates and keep practice consistent across all hospitals. When each substitution is paired with updated dosing guides, clinical pearls, and stocking recommendations, both frontline teams and purchasing teams can act confidently and stay aligned with clinical direction.

Establish a Real-Time Communication Framework Across All Sites

Real-time communication is essential for maintaining alignment during fast-changing events. Site-level dashboards with up-to-date inventory, purchasing, and utilization data keep leaders informed of shifting conditions. As risks evolve, automated notifications highlight critical thresholds, new substitutions, or changes in risk status.

Rapid-response loops for validating on-hand counts and burn rate changes ensure data accuracy when events move quickly. With accurate data in place, concise operational summaries allow executives to make timely system-wide decisions.

Enable Faster Operational Execution During Active Shortages

Once communication and decision pathways are aligned, teams can execute purchasing and redistribution strategies quickly. ShortageCheck’s planning tools support runout tracking and inventory balancing across facilities. Low, medium, and high risk flags, based on inventory days-on-hand per site, give teams a consistent signal that helps determine when to escalate conservation, substitution, or redistribution so actions remain consistent across sites.

This real-time data also supports immediate adjustments to purchase quantities, supply redirection, or emergency orders. Turn Shortage Response Into a Repeatable, Long-Term Resilience Strategy

When coordination practices are applied consistently, it helps transform reactive response into a system-wide resilience program. Technology platforms support this shift by reducing manual burden and centralizing workflows across pharmacy and supply chain teams.

With that foundation in place, pharmacy teams can track trends in supplier reliability, shortage patterns, and risk categories to anticipate future constraints rather than simply respond to them. Documenting lessons learned further refines playbooks and strengthens escalation logic. Executive dashboards then highlight long-term resilience gains and operational improvements that support strategic decision-making.

To strengthen coordination between pharmacy and supply chain teams during shortages, consider a unified technology ecosystem that incorporates shortage prediction, cost optimization, and inventory management across your entire system.