With about half of their 48 operating rooms using pharmacy kits, Brigham and Women’s Hospital in Boston, Massachusetts was using kits faster than they could restock them. Manually restocking the kits at that pace caused a crush of work load for both pharmacists and technicians, leaving concerns about kit inventory accuracy. According to Nicole Mascolo, a pharmacist at Brigham and Women’s, “We wanted to increase the safety of the kits. There wasn’t always someone there to double check the kits after technicians had restocked them so time management and safety were the key reasons to automate this process.”

With about half of their 48 operating rooms using pharmacy kits, Brigham and Women’s Hospital in Boston, Massachusetts was using kits faster than they could restock them. Manually restocking the kits at that pace caused a crush of work load for both pharmacists and technicians, leaving concerns about kit inventory accuracy. According to Nicole Mascolo, a pharmacist at Brigham and Women’s, “We wanted to increase the safety of the kits. There wasn’t always someone there to double check the kits after technicians had restocked them so time management and safety were the key reasons to automate this process.”

Zero Errors Mean Zero Reasons to Worry

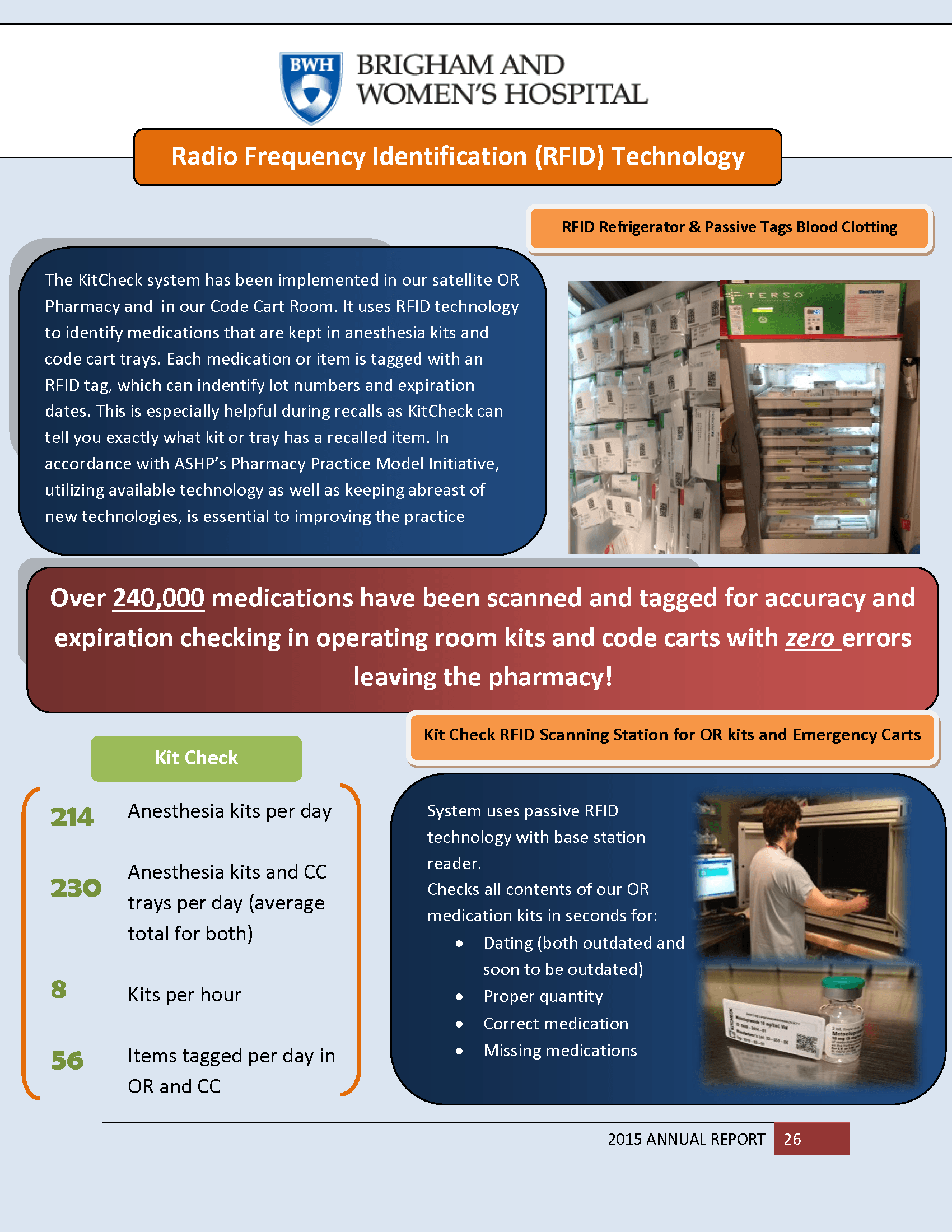

To say they achieved their objectives is an understatement. After automating their kit restocking process with Kit Check, the hospital tracked over 240,000 medications in their OR trays with zero errors over the course of tens of thousands of kit restocks according to their Department of Pharmacy 2015 Annual Report.

“It allows us to feel better at the end of the day when we know the kits are stocked accurately. We have lots of different kinds of kits. For example, we had few neuro kits and sometimes they were all checked out. When one returned, we had to turn it over right away. Now, that isn’t a problem,” said Mascolo.

Time Well Spent Due to Lower Workload and Easier Shortage Management

In addition to safety being a concern, manually restocking hundreds of kits a day took a significant amount of time. Mascolo says after implementing Kit Check “there was a significant decrease in our workload.” This also leaves more time for patient care and other important projects. “It really has been nice and helped us make a lot of changes such as freeing up the tech and co-op to do more things and focus on safety and other important areas. For example, there is typically a co-op from Northeastern and now they get to do more clinical work,” said Mascolo.

In addition to safety being a concern, manually restocking hundreds of kits a day took a significant amount of time. Mascolo says after implementing Kit Check “there was a significant decrease in our workload.” This also leaves more time for patient care and other important projects. “It really has been nice and helped us make a lot of changes such as freeing up the tech and co-op to do more things and focus on safety and other important areas. For example, there is typically a co-op from Northeastern and now they get to do more clinical work,” said Mascolo.

Automating recalls and drug shortages has also delivered significant time savings. When a recall was issued, the staff used to pull every OR kit and code cart back to the pharmacy to check for the recalled item. Today, a technician is solely in charge of recalls and “the process is pretty easy now.” Mascolo also mentioned how Kit Check helps organize kits despite frequent drug shortages. “We follow the kits needing rework report which is very helpful. We know which need to be reworked even if they were dispensed and can fix them when the shortage drugs are available.”

Pharmacist and Technician Approved

Kit Check has been embraced by both pharmacists and technicians alike at Brigham and Women’s. The technicians were hesitant at first but “after a while they realized it’s really easy. The learning curve was short and the process is pretty streamlined now.” And Mascolo said if Kit Check were to disappear, the pharmacists “would be very upset. If the pharmacists had to go back to checking kits, it would also significantly slow down workflow.”

Kit Check has been embraced by both pharmacists and technicians alike at Brigham and Women’s. The technicians were hesitant at first but “after a while they realized it’s really easy. The learning curve was short and the process is pretty streamlined now.” And Mascolo said if Kit Check were to disappear, the pharmacists “would be very upset. If the pharmacists had to go back to checking kits, it would also significantly slow down workflow.”